How I Got Started Making Air Engines

Although I refer to the engines as Pneumatic or Air Engines they could of course run off any source of pressure or vacuum, liquid or gas as long as the material they are made out of can hold up to it.

When I decided to build my first pneumatic engine I had already designed and constructed a couple of Stirling Engines for my wood stove. The Striling Engines were both enjoyable and frustrating projects. It can take quite a bit of tweaking to get a Stirling Engine that runs across a wide range of changing temperatures. After that I wanted to make an engine that ran with more force.

An air powered engine seemed like a good option for a hobby engine that I could run indoors. No heat source, no water mess from steam, no smelly gas or exhaust to upset the rest of the household and lastly I believed it could made with my basic set of wood working tools.

I didn't set out to come up with my own engine design I just wanted something relatively simple and satisfying to build. When I started to look at different Air/Steam engine designs, I thought why so many parts. They all seem to have a separate assembly for the valve other than the power piston. Granted you would need that for single cylinder engine.

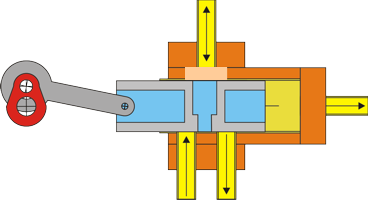

The Piston-Valve

Once I had it in my head that the power piston should be the valve I could not get it out without to building one. Immediately I tried to build a one cylinder version without thinking it through. It quickly became obvious, just like heat engines the pressure control needed to be 90° out of phase with the power piston. This meant for the idea to work there needed to be at least two cylinders. I am sure there other people who have made piston valves but I have not seem them arranged as an engine. In the end the piston is just a simple pneumatic switch controlling air to the piston next to it.

Radial Layout

My first version of the engine was the radial configuration. I chose that layout for one simple reason; I was running out of bearings. In the radial configuration all the pistons attach with a single bearing. Also the layout makes for a very simple crankshaft when compared to the inline four version of the engine. Beyond that I thought making the piston cylinders in a way that could be removed would allow me to attach them to different frames making different engine layouts, or perhaps pneumatic logic circuits. While true, I never actually did that.